Products&Services

Product details

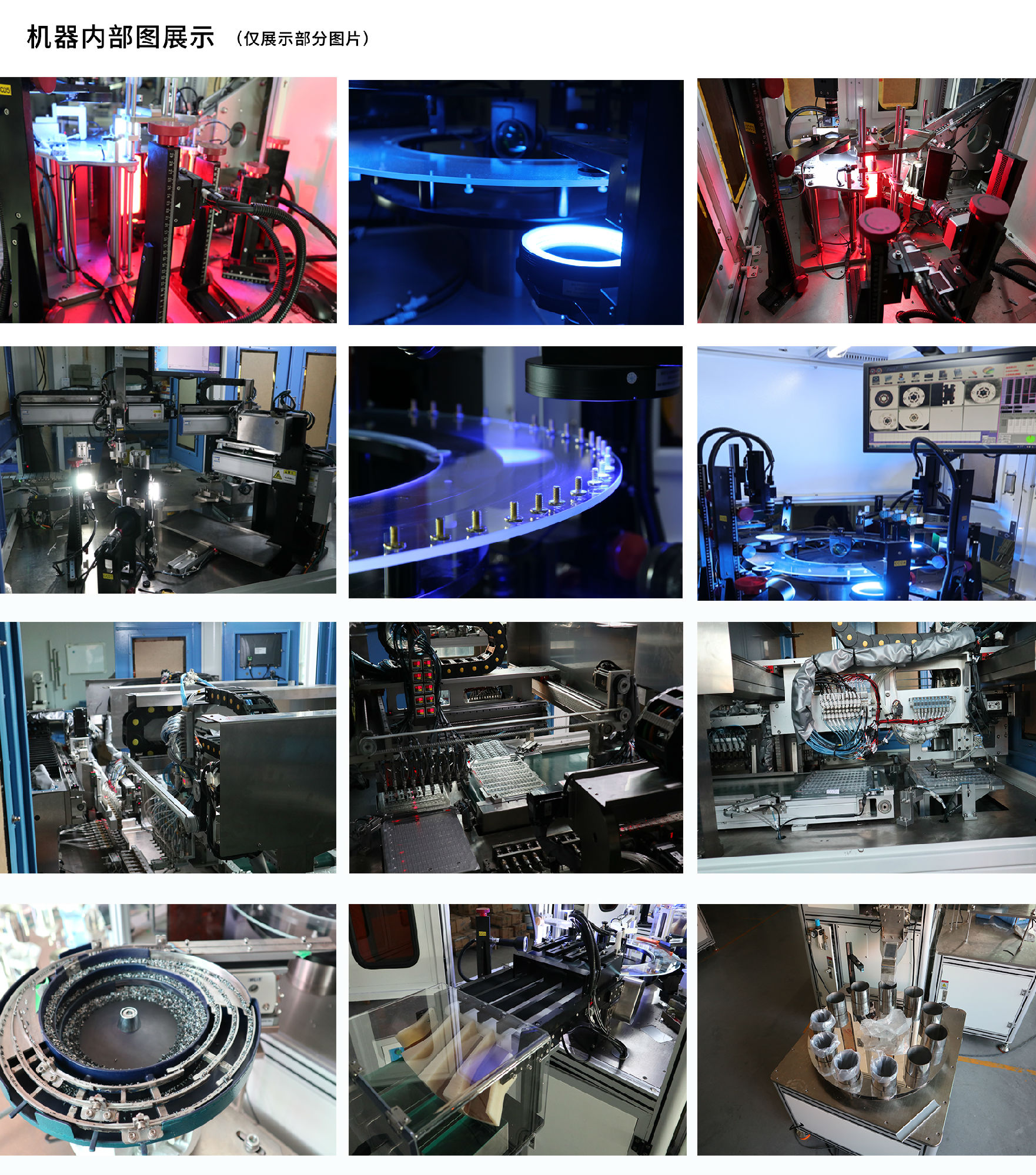

Visual inspection equipment mainly consists of industrial cameras, industrial lenses, visual inspection systems, light sources, optical glass, etc.

1. The interface methods for industrial cameras include USB2.0 industrial cameras, USB3.0 industrial cameras, and gigabit website industrial cameras. However, gigabit website industrial cameras are commonly used, mainly characterized by fast data transmission.

2. There are two types of industrial cameras: CCD industrial cameras and CMOS industrial cameras. CMOS industrial cameras belong to static photography cameras, which means that the product is photographed and analyzed without moving. They are mainly used on devices with low detection speed requirements such as one click detection. CCD industrial cameras are mainly used on dynamic photography devices, suitable for mass testing, so their applications are very wide.

3. Industrial cameras are divided into black and white industrial cameras and color industrial cameras. Black and white industrial cameras are the most commonly used. The photos taken by black and white industrial cameras have clearer edges than color cameras, and the images taken by black and white industrial cameras are more conducive to visual inspection system capture. The photos taken by black and white industrial cameras only have black and white pixels, and the detection speed will be faster. Color industrial cameras, due to their complexity, have a much slower detection speed, So color industrial cameras are mainly used for detecting products with complex colors.

The principle is to add a set of movable lenses to the lens of the lens, adjust the lens to achieve focusing or focusing, and then change the image distance.

1. A commonly used standard telephoto lens with a viewing angle of 30 degrees refers to a lens with the main light parallel to the lens, the telephoto on the object side, the telephoto on the imaging side, and the telephoto heads on both sides.

2. Wide angle lenses and ultra wide lenses, with a viewing angle of 55 degrees or more, include a second lens with a negative bending force, a third lens, a fourth lens with a positive bending force, a fifth lens with a negative bending force, and a sixth lens with a positive bending force in order from the object side to the image side along the optical axis.

Among them, the object side of the first lens is convex, and the image side is concave. The object side of the second lens is concave, and the image side is convex. By adjusting the above lenses and their relative relationships, sufficient field of view angles, corrected aberrations, and good imaging quality can be provided.

3. The zoom lens can change the zoom length value at any time, making it very convenient for application and widely used. However, due to the large number of lenses and complex structure of the zoom lens, the large relative aperture cannot be made too large, otherwise the illumination brightness of the shot is low and the pixel points are deformed, which is not suitable for the system to capture features.

3、 Light source

The light source is mainly divided into front lighting and back lighting. Front lighting is used to detect surface features of objects, and back lighting is used to detect the purity of object contours or transparent objects.

1. The ring LED light source is used to detect the small volume, the light source can shine for just one circle, the light location is relatively concentrated, and the Color index is relatively good.

2. A low angle circular light source is used for shooting when there is no obstruction on the protruding edge of the side.

3. The shadowless ring light source can completely eliminate shadows through multiple reflections on the inner wall of the hemisphere, playing a special role in detecting uneven surfaces.

4. LED strip light source is used for lighting products that are relatively long or wide. If too many light sources are combined, there will be shadow delay, so strip light source needs to be used.

5. Coaxial light source, coaxial lighting refers to the parallel passage of light through the vertical mirror of the lens, which is ideal for observing very flat or polished surfaces, meaning it is suitable for detecting the appearance of very flat products.

1. Visual software is the most difficult and core part of visual inspection equipment. The system needs to analyze the images taken by the camera and detect cracks, electroplating defects, bubbles, missing materials, excessive materials, scratches, black spots, color differences, deformation, mixing, tooth rubbing defects, sharp edges, dirt, and text in the image product.

2. The company currently has two software development teams and two industry-leading detection systems, the artificial intelligence system visual detection system, which can automatically train and learn through simple operations. It simulates the neural network in the human brain by creating an artificial neural network.

Just like solving problems with the human brain, it can avoid the problems of small and mild features of product defects, as well as the difficulty of traditional detection systems in judgment.

5、 Optical glass

Ordinary glass cannot be applied to visual inspection equipment, and the transmittance of the glass must exceed 95%, otherwise it will affect the judgment of the equipment. Therefore, optical glass with a transmittance of 95% must be selected to improve detection efficiency.