Products&Services

Product details

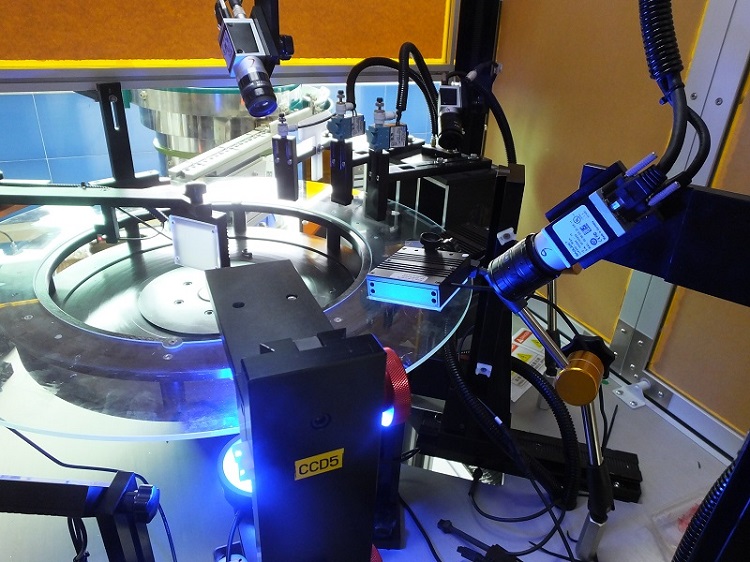

With the acceleration of modern industrial automation, the application fields of machine vision systems are becoming increasingly widespread. Appearance defect detection machines have been widely used in industries such as industry, agriculture, transportation, and even sports, entertainment, etc,

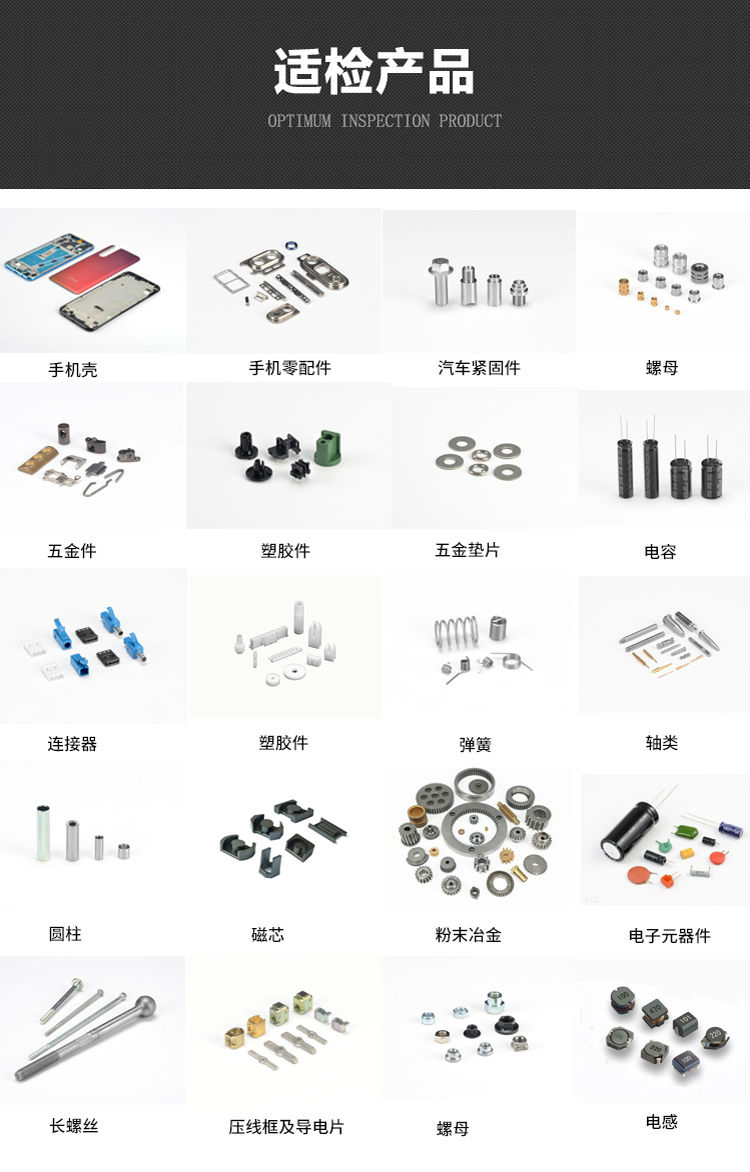

The appearance defect detection machine is suitable for detecting the appearance and dimensional quality of plastic parts, rubber rings, O-rings, screws, nuts, oil seals, metal stamping parts, irregular hardware, electronic components, fasteners, and other products. The appearance defect detection machine automatically selects good and bad products. The appearance defect detection machine utilizes the high transparency of glass, and objects can be stably placed on the detection plate for detection.

1. Non contact measurement, which does not cause any damage to both the observer and the observed, wholesale appearance defect detection machines to improve the reliability of the system;

2. Having a wide spectral response range, such as using infrared measurements that are invisible to the human eye, which expands the visual range of the human eye;

3. The appearance defect detection machine also has the advantages of simple maintenance, low technical requirements for operators, and long service life.

3、 Reference for inspection items of screw and nut appearance defect detection machine:

1. Pinhole concentricity

2. Screw length

3. Head shape, text

4. Broken needle, plug hole

5. Screw bending

6. Tail shape

7. With or without electroplating

8. True roundness

9. Cephalic fissure

10. Is there any burrs

11. Skew teeth and poor tooth rubbing

12. Head sleeve detection

13. Head width and height

14. Dental base diameter

15. Tooth outer diameter

16. Interdental distance

17. Inner diameter of screw tooth

18. Cross depth

The nut appearance defect detection machine is suitable for detecting hanging fasteners such as M3~M20 round head screws and bolts. It can quickly complete various detection indicators, with a detection speed of 600 pieces per minute and an accuracy of ± 0.01mm. During the detection process, there will be no tooth damage.

The nut appearance defect detection machine has innovative humanized design machine and system, simple operation mode, friendly user interface, appearance defect detection machine, nut appearance defect detection machine appearance dimension detection: length, height, diameter, mixture, tooth outer diameter, inner diameter, opposite side, diagonal, concentricity, roundness, angle, sharpness, etc.

Nut appearance defect detection machine defect detection: can detect tooth damage, oblique teeth, head cracks, presence or absence of teeth, rotten teeth, bad teeth, poor tooth rubbing, burrs, missing materials, internal hole blockage, burrs, marks, etc. Power supply voltage: three-phase 380V, 50Hz, rated power: 1kW, air pressure: 0.35-0.7MPa, working temperature: 0 ℃~50 ℃, storage temperature: -20 ℃~60 ℃.